The production schedule about led grow light of HYPHOTONFLUX (part 5)

✿After the introduction of the first four parts. I think that everyone has a general understanding of our products.HYPHOTONFLUX has been always asking ourselves with strict standards to achieve high quality. Each product has undergone multiple stages of testing before shipping to you. Now we are going to introduce the last part of the production schedule. After this part, You will see the complete production and testing process of the lights before arriving in your hands.

✿Step 13: Aging Test

Each light needs to go through an 8-hour aging test before leaving the factory, which ensures you get high-quality lights.

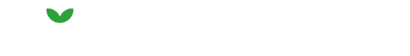

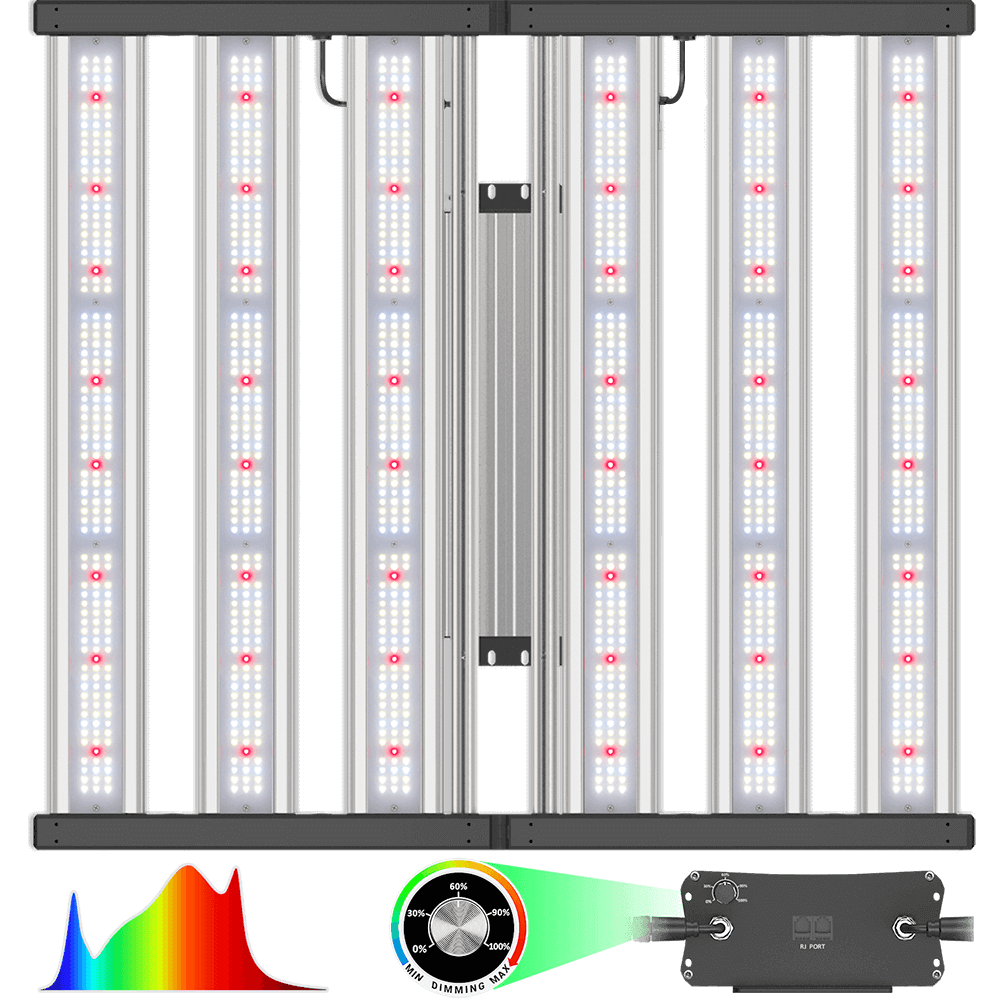

✿Step 14: Dimming and Controller Test

After 8 hours Aging Test, all lights need to make a series of quality testing again before package.

1.Connect the light and power

2.Adjust the dimmer and test the dimming function

3.Wear special glasses and check if LEDs work well normally and the brightness is uniform

4.Connect the controller to test if the light works well with controller

✿Step 15: Waterproof Test

The QA staff will select sample fixtures randomly to make the waterproof test.

1.Keep sprinkling for 5 minutes when the light is working

2.After the Sprinkling test, Wipe off the water on the fixture and driver box

3.Connect the DC cord and power on

4.Adjust the dimmer to test if the light works well

If all samples tested are qualified, the whole batch of fixtures will be packaged and shipped

✿Step 16:Package

After checking for defects on the surface of the Aluminum frame and driver box.

1.Package the fixture, driver box, accessories bag, and user manual into the carton.

2.Check again all accessories are inside of the box before sealing the package.

3.All packages need to be weighed and recorded to ensure nothing is missed.

4.Double package to protect your privacy

✿Step 17:Loading Container

1.Place the well-packaged products on the pallet;

2. Wrap with plastic film to prevent falling;

3. Send the pallet goods to the loading area;

4. Lift the pallet into the container with a forklift;

The lights are getting closer and closer to your hand after everything is ready to go.

✿The above is part 5 of the production schedule, thank you for reading!

As a small brand company, we know that product quality is the cornerstone of our growth. Our vision has always been to provide growers worldwide with commercial-grade lights at the most affordable price. If you have any questions or suggestions about the product pls feel free to contact us.Or you want to watch related videos, you can watch it on our YOUTUBE Channel.