REASONS THAT AFFECT THE LIFESPAN OF LED GROW LIGHT

✿ If the failure of the power supply or LED driver is not considered, the lifespan of LED diode is one of the reasons that affect the lifespan of led plant light.✿ The lifespan of LED diode is represented by its light loss. It is simply to say that the brightness is getting darker and the light intensity (Photosynthetic Photon Flux Density) is getting weaker by the time.

✿ The light loss of LED diode is related to its junction temperature which is PN junction temperature. It is simply to say that Higher junction temperature will start light loss earlier and the lifespan of LED diode will get shorter. The most important key to extend its lifespan is reducing the junction temperature.

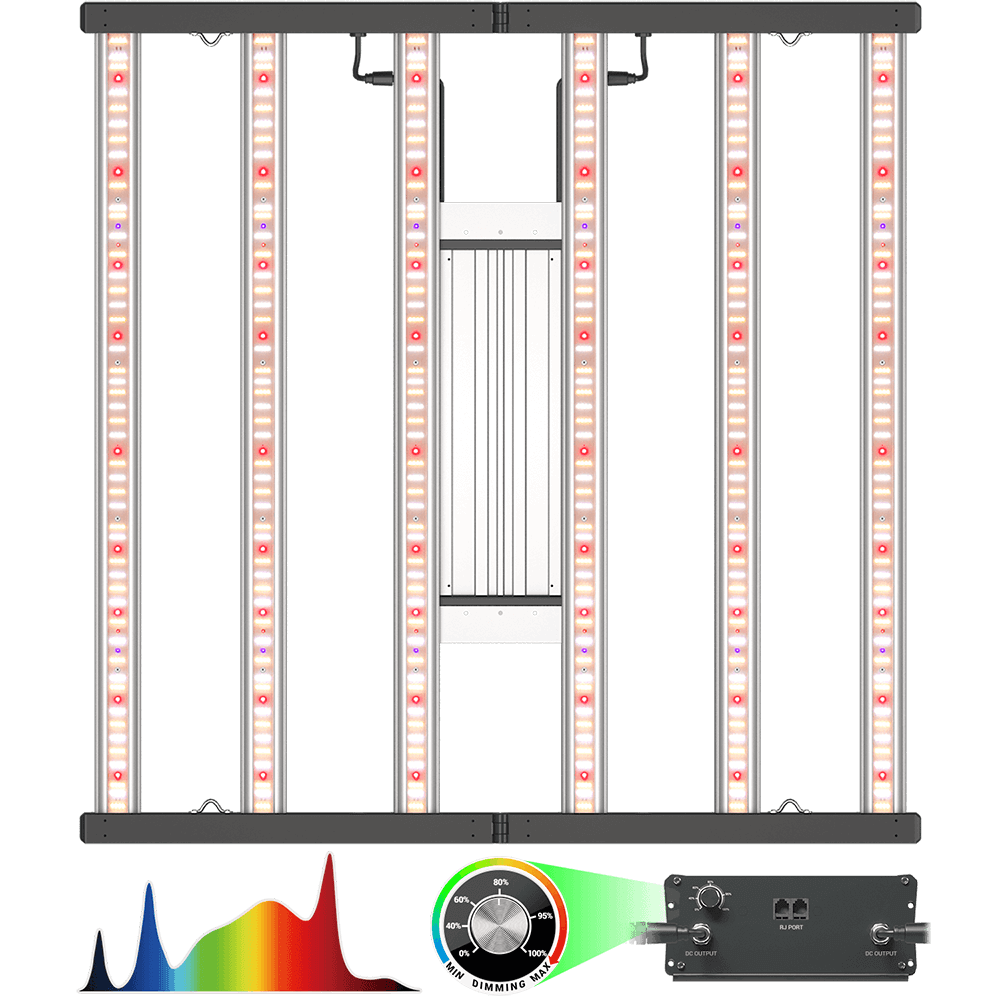

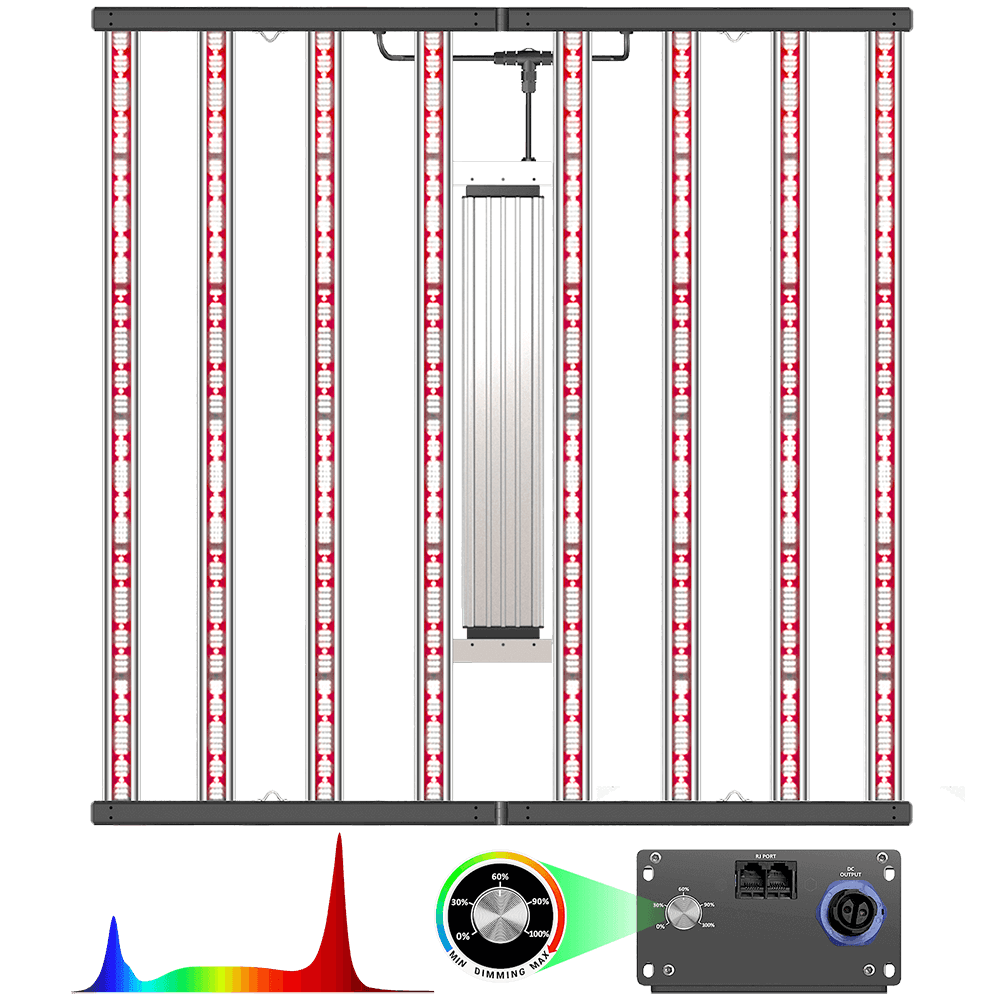

✿ HYPHOTONFLUX HPF series led grow lights are all powered by Samsung lm301b and Osram 660nm LED diode which is the best quality components in LED grow light industry recently. Let us make an example as Samsung lm301b TM21 report in below:

1. When the junction temperature is 105degree, Photon Flux Maintenance Q90 is more than 19,000 hours;

2. When the junction temperature is 85degree, Photon Flux Maintenance Q90 is more than 33,000 hours;

3. When the junction temperature is 55degree, Photon Flux Maintenance Q90 is more than 43,000 hours.

TM-21-11 ReportProjecting Long Term Photon Flux Maintenance of LED Light Source

| Table 1: Report at each LM-80 Test Condition | ||||||||

| Test Condition 1-55°C Case Temp | Test Condition 2-85°C Case Temp | Test Condition 3-105°C Case Temp | ||||||

| Sample size | 20 | Sample size | 20 | Sample size | 20 | |||

| Number of failures | 0 | Number of failures | 0 | Number of failures | 0 | |||

| DUT drive current used in the test(mA) | 180 | DUT drive current used in the test(mA) | 180 | DUT drive current used in the test(mA) | 180 | |||

| Test duration (hours) | 12,000 | Test duration (hours) | 12,000 | Test duration (hours) | 12,000 | |||

| Test duration used for projection (hour to hour) | 6000 - 12,000 | Test duration used for projection (hour to hour) | 6000 - 12,000 | Test duration used for projection (hour to hour) | 6000 - 12,000 | |||

| Tested case temperature (°C) | 55 | Tested case temperature (°C) | 85 | Tested case temperature (°C) | 105 | |||

| α | 2.345E-06 | α | 3.094E-06 | α | 4.978E-06 | |||

| β | 55 | β | 0.997 | β | 0.991 | |||

| Reported Q90(12k)(hours) | 43,000 | Reported Q90(12k)(hours) | 33.000 | Reported Q90(12k)(hours) | 19.000 | |||

✿ The light loss factor is different regards to the quality of LED diode due to their thermal resistance and heat dissipation. Let us make an example of Samsung lm301b diode which selected by HYPHOPTONFLUX HPF series grow lights. The light loss factor of Samsung lm301b is more stable at different junction temperature.

Photon Flux Maintenance

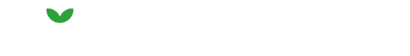

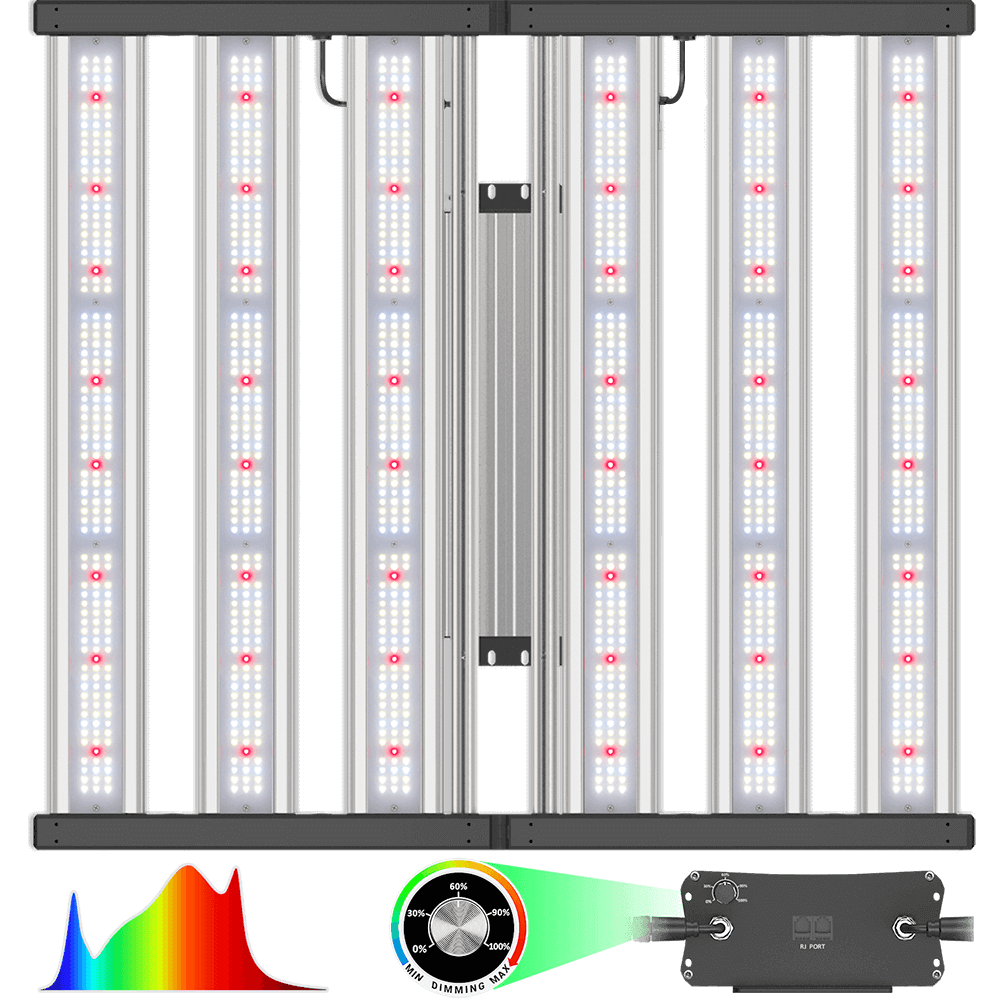

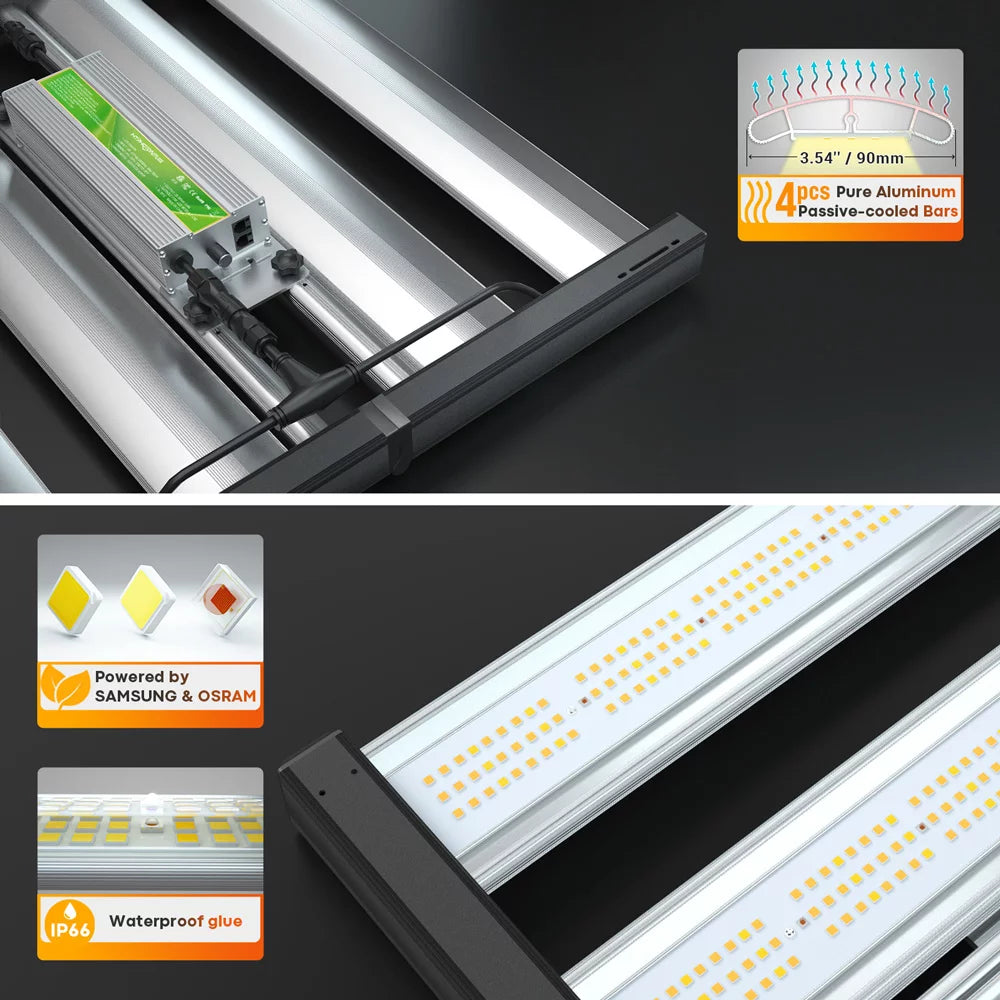

✿ HYPHOTONFLUX HPF4000 used 6 pcs pure aluminum light bars (each bar's width is 90mm/3.54'', wider than any other led light bar) for better heat dissipation and cooling. At the same time, the stripy design on the Aluminum surface extend the cooling area. The good heat dissipation product is not only saving your cost in cooling devices but also extending the lifespan of the grow lights.

✿ Here is the temperature report of HYPHOTONFLUX HPF4000. When working temperature is 25degree, The Samsung lm301b junction temperature is only 58.9degree and the Aluminum housing temperature is 51.2degree.

| No | Testing Point |

Voltage tested/Meanwell XLG240×2 |

Working Temp. | Input Power | |

| 120V/60Hz | 240V/50Hz | ||||

| NO: 1 | LED 660nm | 50.1℃ | 59.7℃ | 25.0℃ | 498W/120V |

| NO: 2 | LED White | 58.9℃ | 59.1℃ | 25.0℃ | 492W/240V |

| NO: 3 |

Aluminum Board |

53.8℃ | 53.9℃ | 25.0℃ | |

| NO: 4 |

Aluminum housing |

51.2℃ | 50.9℃ | 25.0℃ | |

| NO: 5 | Driver Tc | 67.3℃ | 62.0℃ | 25.0℃ | |