The production schedule about LED grow light of HYPHOTONFLUX (Part 1)

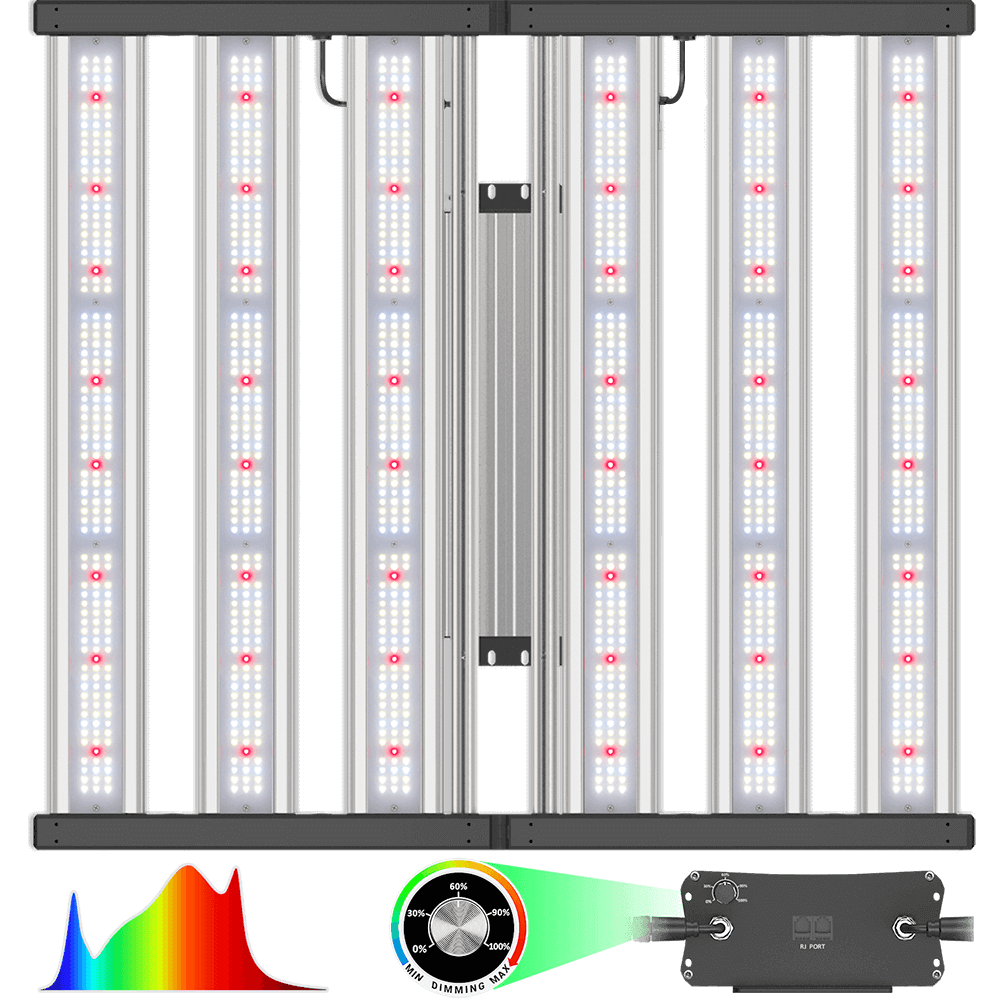

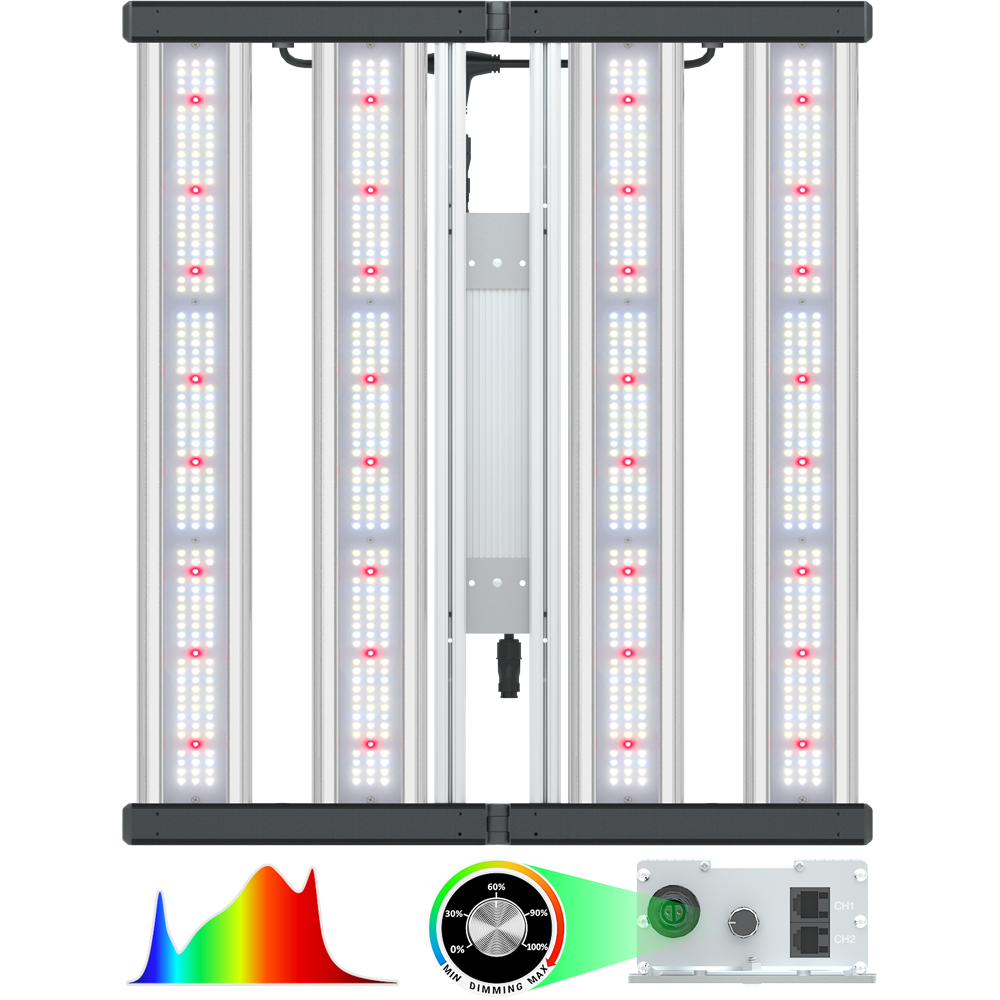

✿ As a grow light manufacturer with 11 years experience, we established the brand HYPHOTONFLUX to provide growers worldwide with commercial-grade LED grow lights at the most affordable prices.✿ In order to achieve a household name, we are dedicated to provide the highest quality and energy-efficient products with high PPF output that allow our customers to maximize the yield of their plants at all stages of the growth cycle.

✿ Supplying a good quality product not only need top quality materials, but also need high quality control management and strict production schedule. HYPHOTONFLUX team will detailed introduce our production schedule in below:

✿ Step 1: Solder paste printing

Solder Paste is applied on the PCB using a soldering machine. We make solder paste printing on PCB with the stencil to make sure LED diode will paste in correct positions of solder pads evenly.

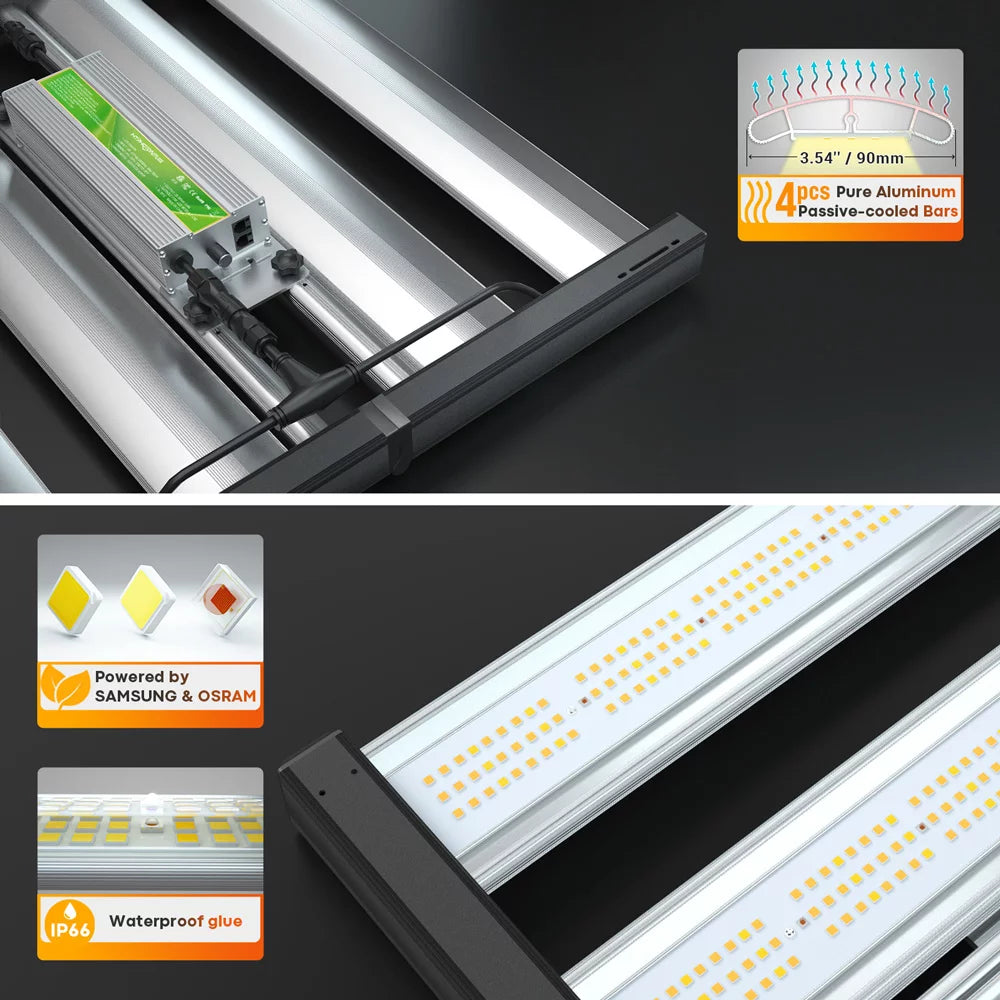

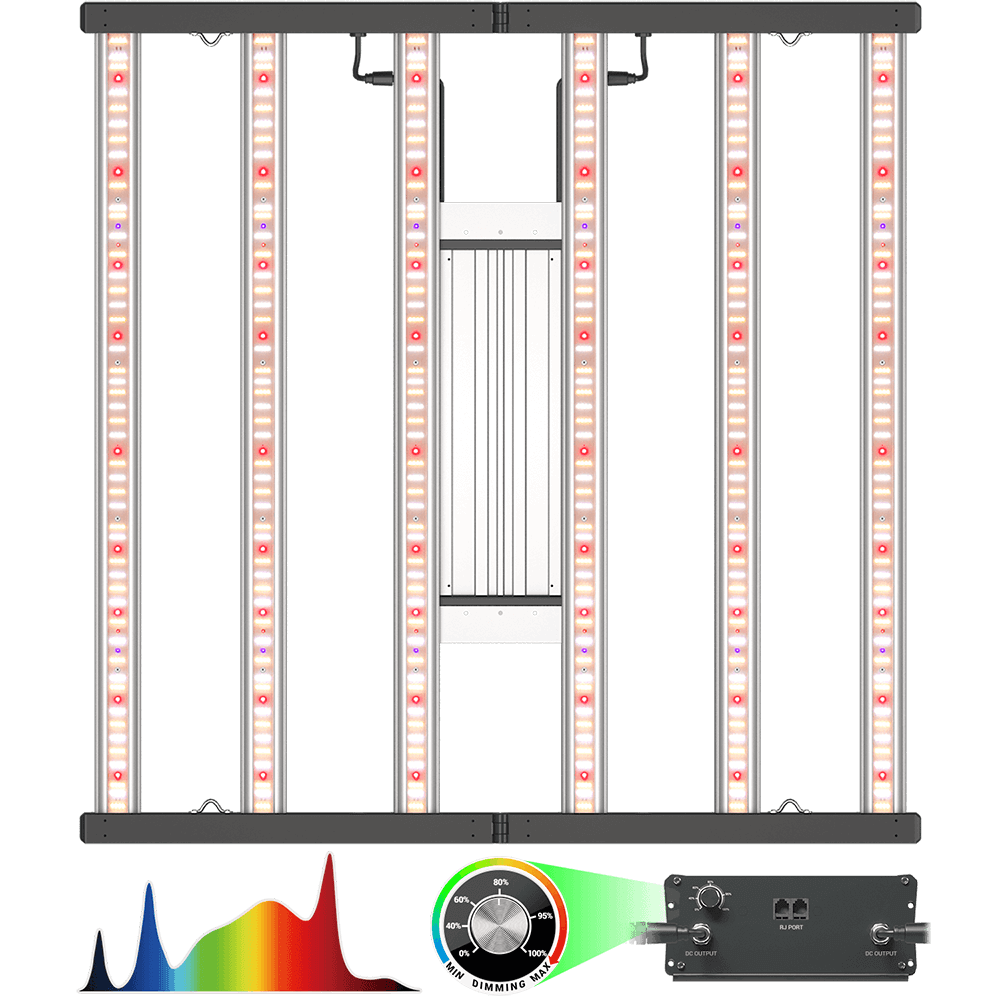

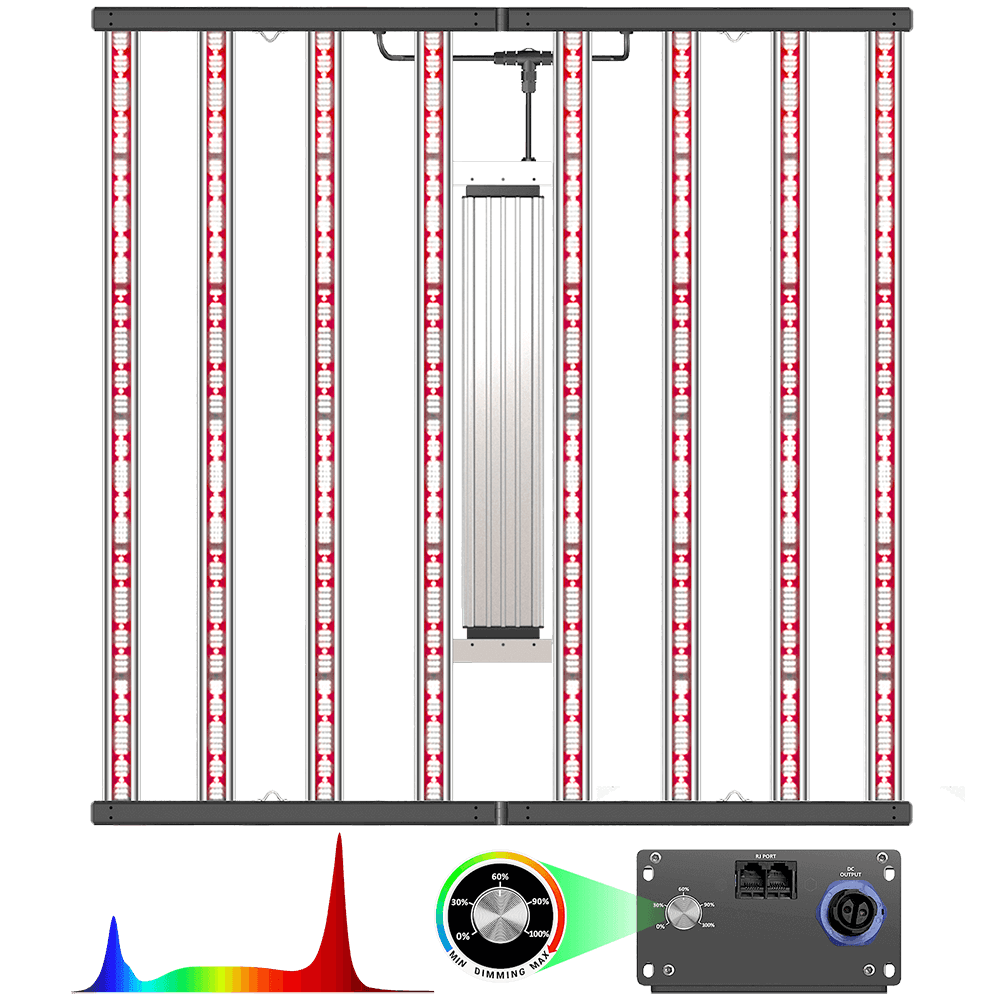

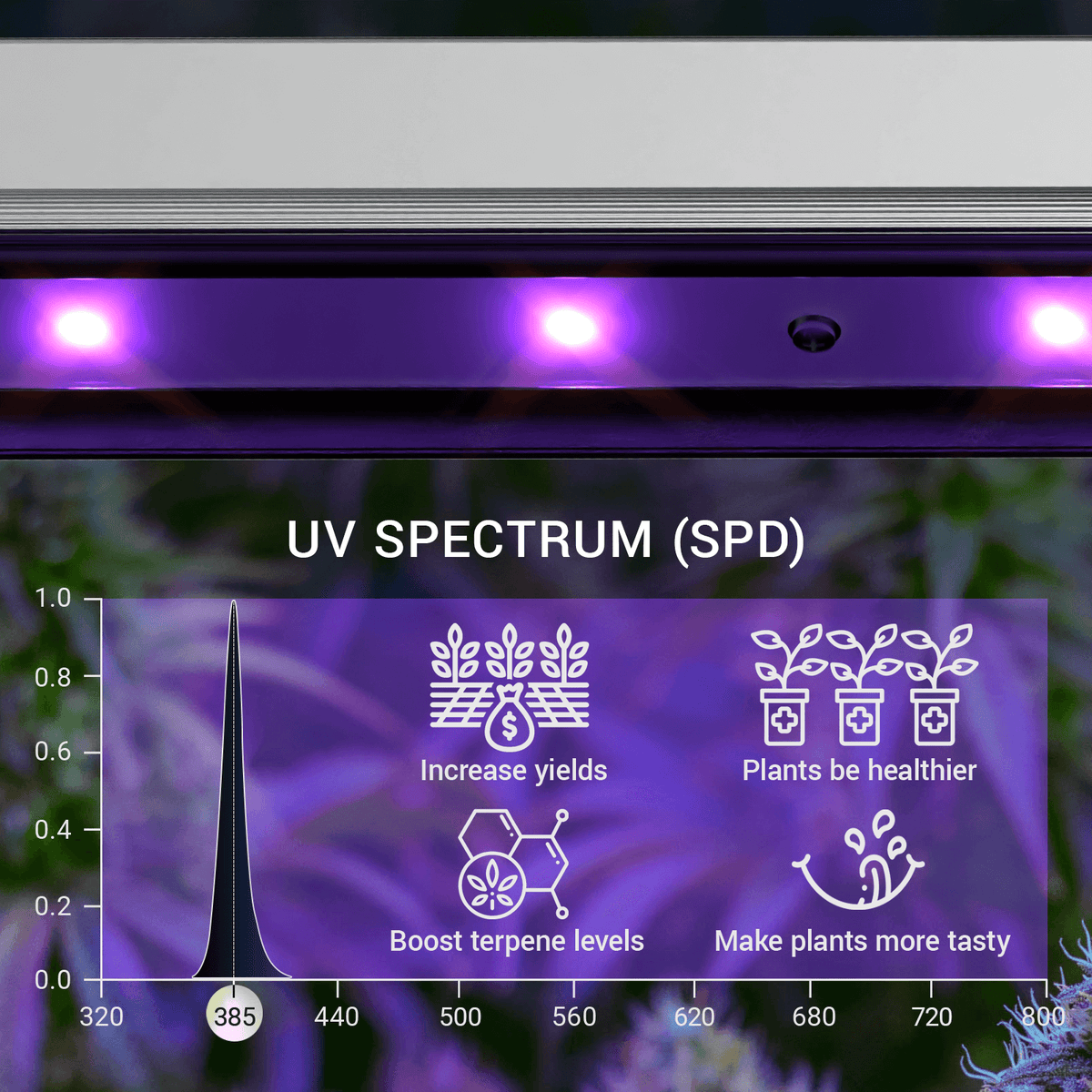

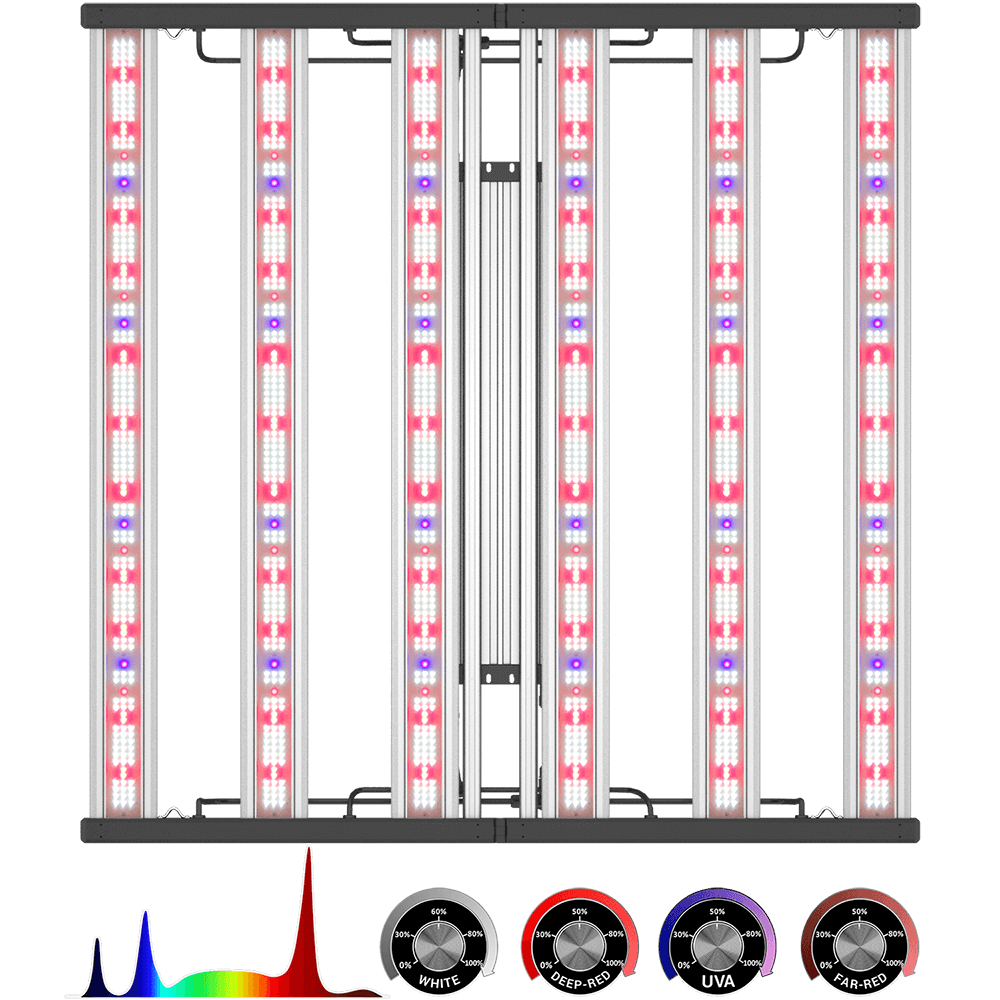

The printed PCB proceed to the pick-and-place machines where they are carried on a conveyor belt and the led diode reels( Samsung diode, Osram deep red, UVA and far-red led etc) are placed on them.

After LED diode was placed, the LED PCB boards are conveyed into the reflow soldering oven which has 8 temperature control systems and 4 temperature Zones:

Pre-heat Zone: The first zone in oven is a pre-heat zone,where the temperature of the board and all the components is raised simultaneously and gradually. Temperature ramp up rate in this section is 1.0℃-2.0℃ per second until it reaches 150℃-180℃.

Soak Zone: The boards will be kept in this zone on temperature from 150℃-180℃ for 60-120 seconds.

Reflow Zone: The boards then enter a zone where the temperature ramp up at 1.0℃-2.0℃ per second to the peak of 250℃-270℃ to melt the tin in the solder paste, bonding the component leads to the pads on the PCB. The surface tension of the molten solder helps keep the components in place.

Cooling zone: A section to ensure solder freezes at exit of heating zone to avoid joint defect.